Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

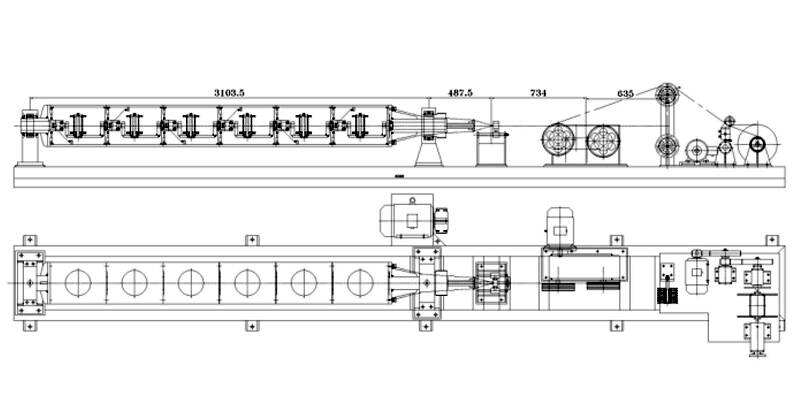

JGG630/12+1 Tubular Stranding machine

The JGG630/12+1 Tubular Stranding Machine is built for high-precision stranding of bare copper wire, aluminum wire, and ACSR. Featuring intelligent tension control, reliable mechanical design, and a robust lubrication system, this machine delivers exceptional wire quality, consistent lay length, and efficient performance. Its advanced structure and user-friendly operation make it an ideal choice for modern cable manufacturers seeking productivity and long-term durability.

Product Features

Magnetic Hysteresis Tension Control

The machine uses a magnetic hysteresis device for accurate tension control, which can be easily adjusted via a touch screen interface for consistent wire quality and flexibility in production.

Shaft-less Bobbin Clamping and Pneumatic Release

Designed with a shaft-less structure, the machine enables automatic mechanical clamping and pneumatic bobbin release, simplifying bobbin changes and reducing setup time.

Direct Motor Drive with Synchronous Pulleys

The AC variable frequency motor directly drives the rotating assembly through synchronous pulleys, ensuring smooth torque delivery and efficient energy use.

Single Wire Preforming for Enhanced Quality

Equipped with a single wire preforming device, this machine enhances the roundness and compactness of stranded wires, boosting both appearance and structural integrity.

Oil Splash Gear Lubrication System

A gearbox with oil splash lubrication minimizes wear and friction in the transmission system, promoting long-lasting, low-maintenance, and efficient performance under continuous operation.

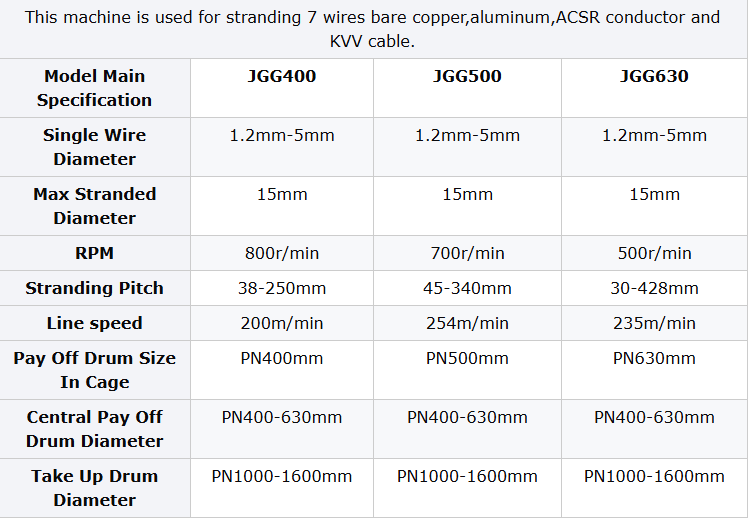

Technical Specifications

Product Advantages

Consistent and Stable Lay Length

The pneumatic braking system allows the stranding cage and traction system to decelerate in sync, ensuring stable and uniform lay length throughout production.

User-Friendly Operation and Quick Setup

The combination of touch screen control and shaft-less design allows operators to make fast adjustments and bobbin changes with minimal effort.

Durable and Low-Vibration Structure

With precision bearings at both ends and a large central bearing, the stranding cage remains stable during high-speed operation, reducing vibration and extending machine life.

Efficient Wire Threading Path

The wire path runs outside the stranding cage for easier wire threading, reducing setup time and improving productivity on the shop floor.

Improved Wire Quality Through Preforming

The built-in preformer significantly enhances the uniformity of the stranded conductor, delivering higher quality final products with improved mechanical characteristics.

Order Information

- Lead Time: 30-180 days

- Payment Methods: T/T, L/C

- Minimum Order Quantity: 1 unit

- Customization: Available

- OEM & ODM: Supported

- After-sales Service: 24/7 online support, on-site visits possible

- Warranty: 1 year

- Workshop Facilities: Specialized production, welding, and assembly workshops

- Quality Control: Experienced QC engineers (15+ years)

- Logistics: Sea freight, plastic film packaging, wooden boxes at extra cost